Details of locking systems

LATEST GENERATION TECHNOLOGY FOR SUSTAINABLE PROJECTS

LATEST GENERATION TECHNOLOGY FOR SUSTAINABLE PROJECTS

TechDaal enclosure systems are developed based on rigorous technical detailing, designed to ensure structural stability, controlled airtightness, and long-term correct performance of the building assembly. Each solution is defined layer by layer, using certified and fully compatible materials, each with a clearly assigned role in load transfer, vapour control, and structural protection. The enclosure details integrate the lightweight steel structure, fixing systems, protective layers, and finishes, enabling precise and predictable execution. These solutions are thoroughly documented to support correct on-site implementation and to maintain compliance with current quality and durability requirements.

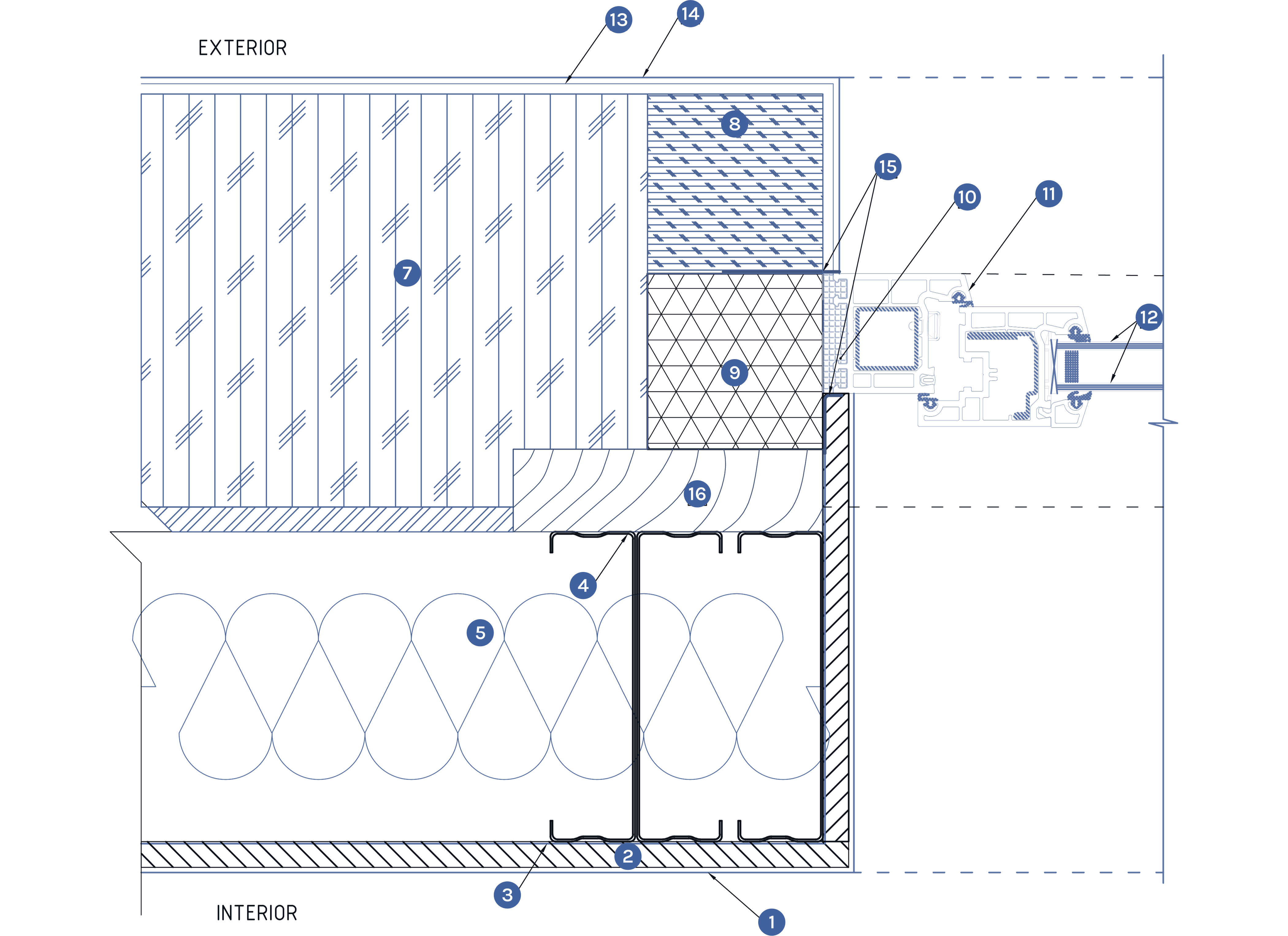

FENESTRATION DETAILS

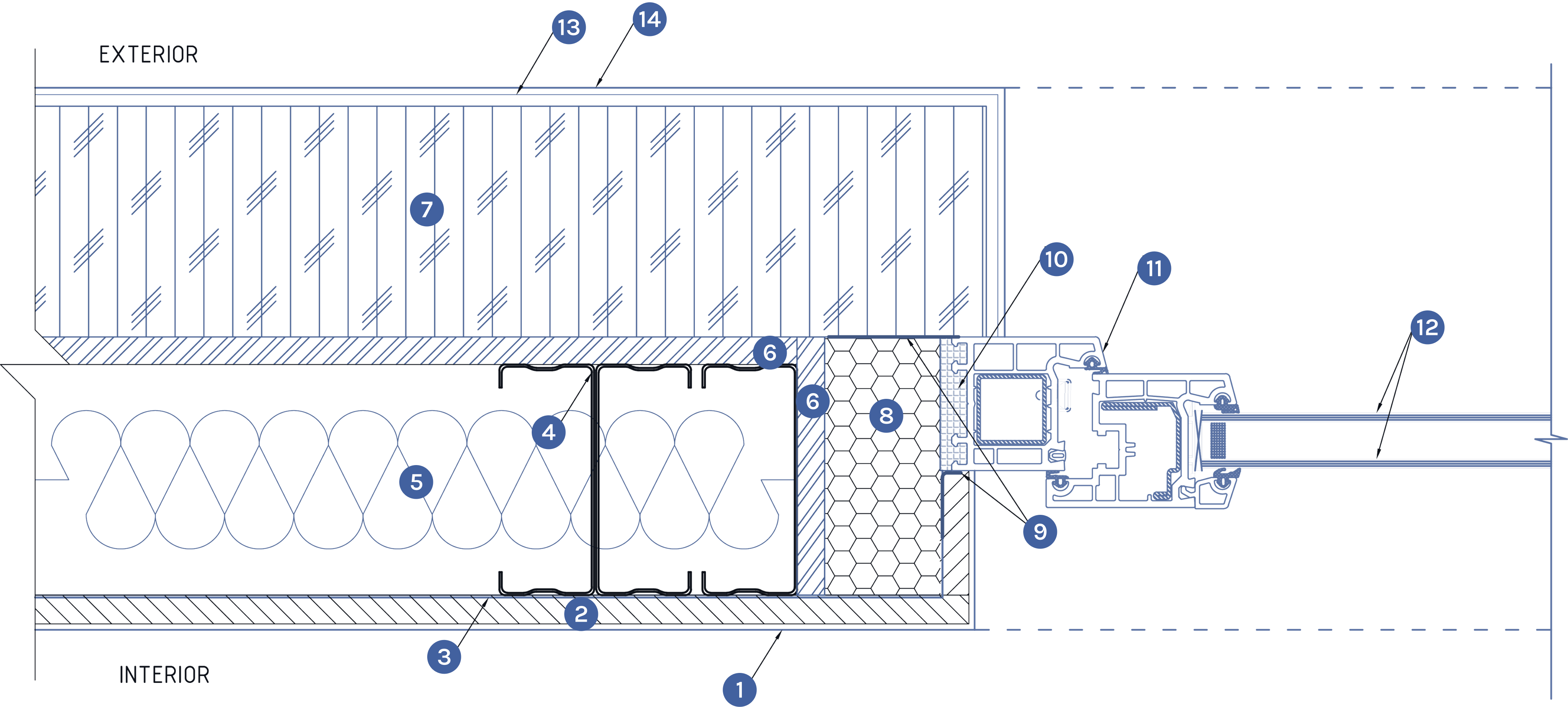

Fenestration fixing detail within lightweight steel wall – horizontal section

1. Interior finish layer: skim coat + washable paint: ~2.5 mm

2. Gypsum plasterboard: 12.5–25 mm

3. Vapour barrier

4. Lightweight steel stud wall, C100 / C150 profiles

5. Mineral wool / cellulose insulation

6. Rigid sheathing board (OSB3, plywood, fibre-cement): min. 12 mm

7. External thermal insulation system (EPS, basalt mineral wool): min. 100 mm

8. Thermal insulation layer (EPS): 50 mm

9. Sealing tape (interior and exterior)

10. Window and door installation foam

11. Window / door frame

12. Glazing unit

13. Reinforced render with fiberglass mesh: ~5 mm

14. Decorative render: ~3 mm

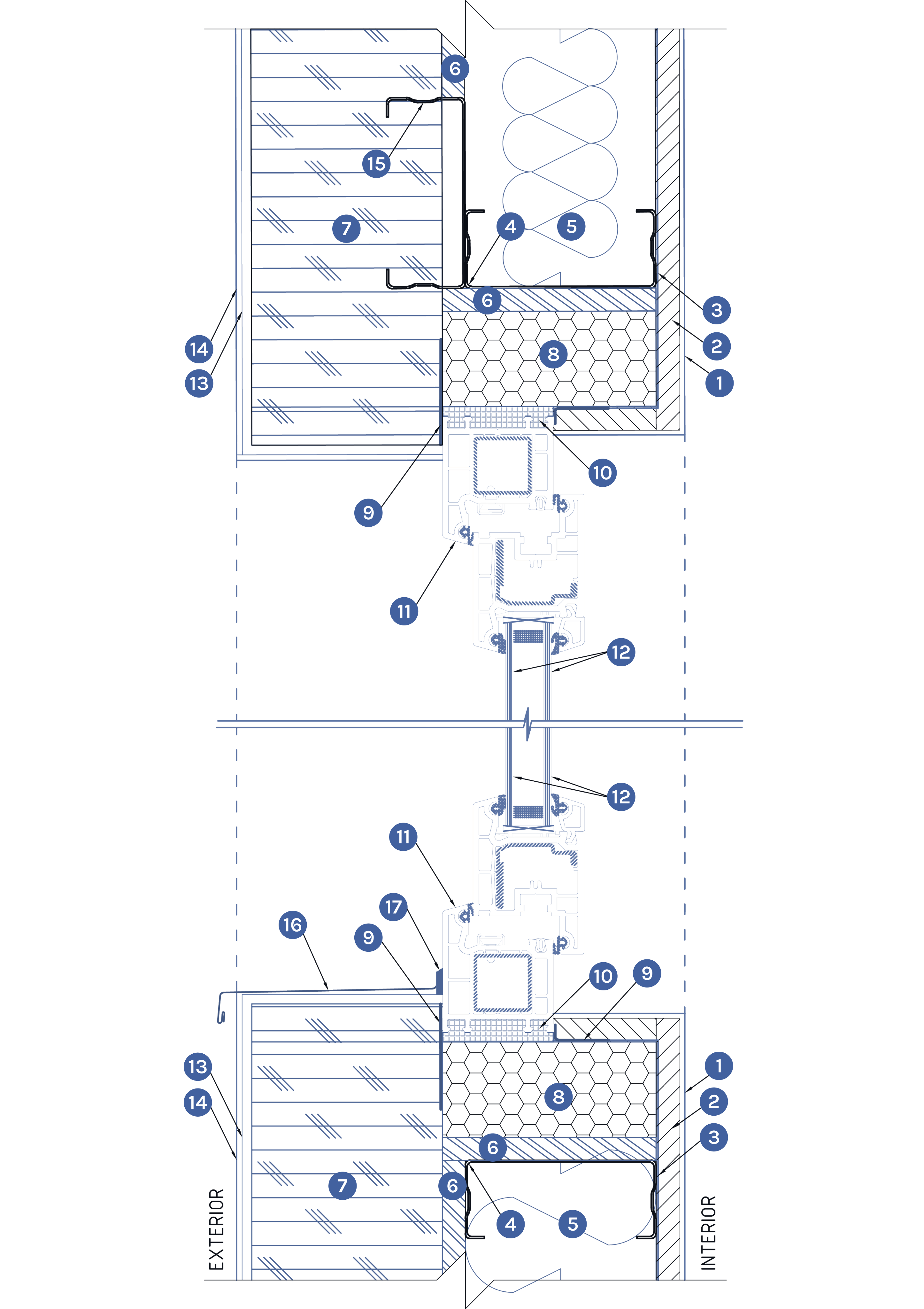

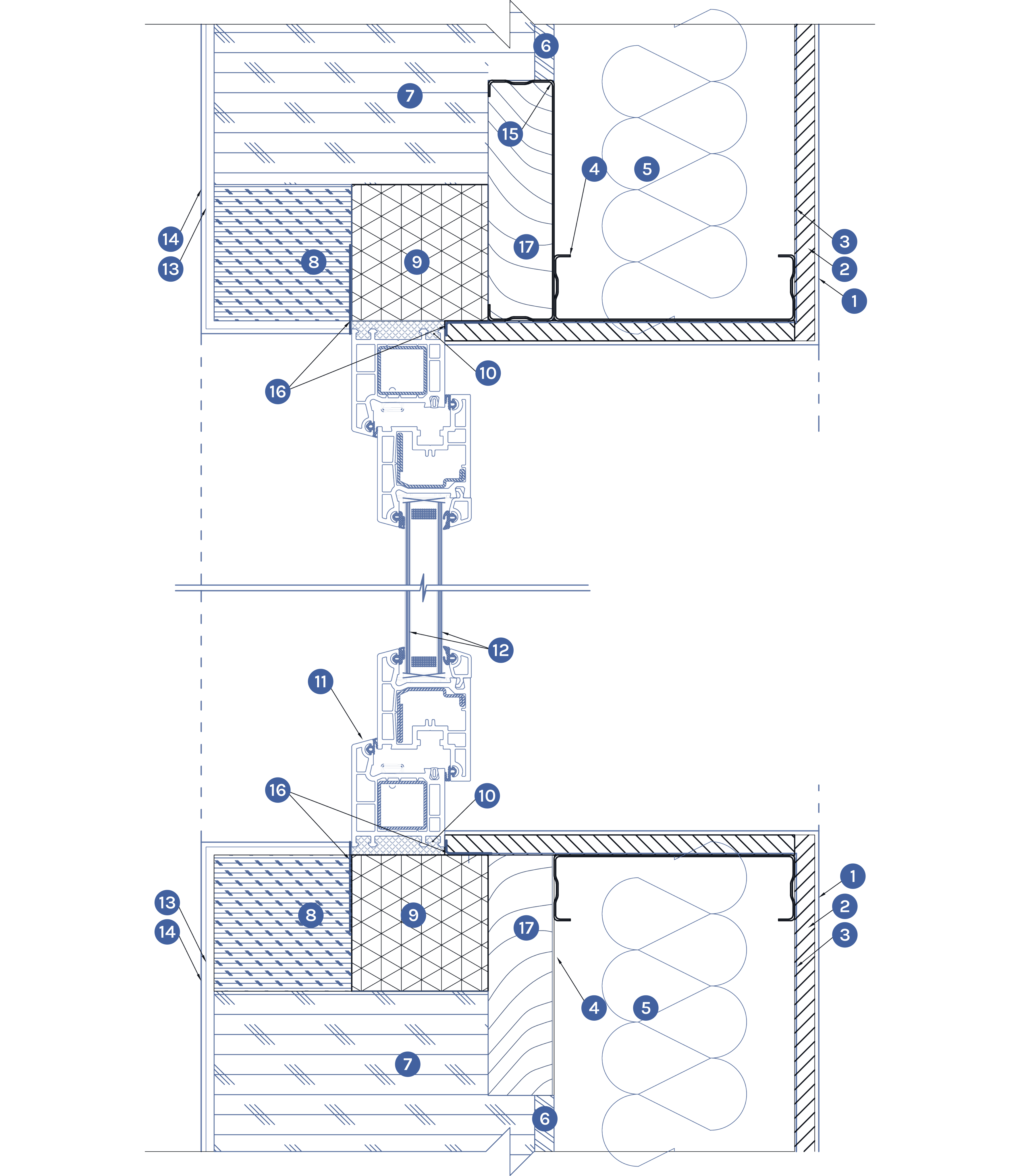

Fenestration fixing detail within lightweight steel wall – vertical section

1. Interior finish layer (skim coat + washable paint): ~2.5 mm

2. Gypsum plasterboard: 12.5–25 mm

3. Vapour barrier

4. Lightweight steel stud wall, C100 / C150 profiles

5. Mineral wool / cellulose insulation

6. Rigid sheathing board (OSB3, plywood, fibre-cement): min. 12 mm

7. External thermal insulation system (EPS, basalt mineral wool): min. 100 mm

8. Thermal insulation layer (EPS): 50 mm

9. Sealing tape (interior and exterior)

10. Window and door installation foam

11. Window / door frame

12. Glazing unit

13. Reinforced render with fiberglass mesh: ~5 mm

14. Decorative render: ~3 mm

15. C-profile lintel reinforcement

16. Window sill with drip edge, adhesively fixed

17. Water-repellent protection layer

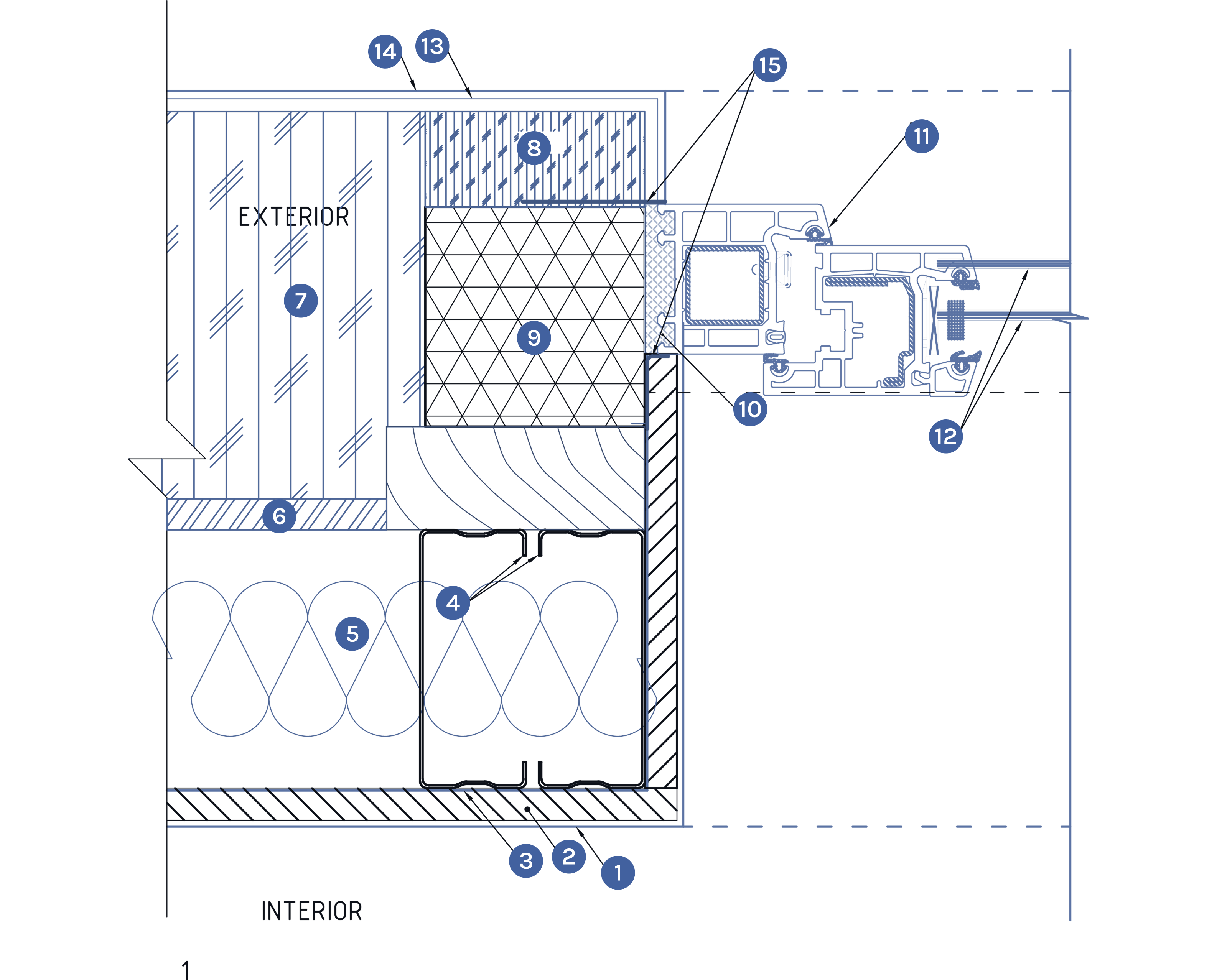

Primary fenestration fixing detail – horizontal section

1. Interior finish layer (skim coat + washable paint): ~2.5 mm

2. Gypsum plasterboard: 12.5–25 mm

3. Vapour barrier

4. Lightweight steel stud wall, C100 profiles

5. Thermal insulation within the steel wall cavity

6. Rigid sheathing board (OSB3, plywood, fibre-cement): min. 12 mm

7. External thermal insulation system (EPS, basalt mineral wool): min. 150 mm

8. Thermal insulation layer (EPS, basalt mineral wool)

9. Pre-frame with polymer adhesive and mechanical fixings

10. Fenestration installation foam

11. Fenestration frame

12. Glazing unit

13. Reinforced render with fiberglass mesh: ~5 mm

14. Decorative render: ~3 mm

15. Sealing tape (interior and exterior)

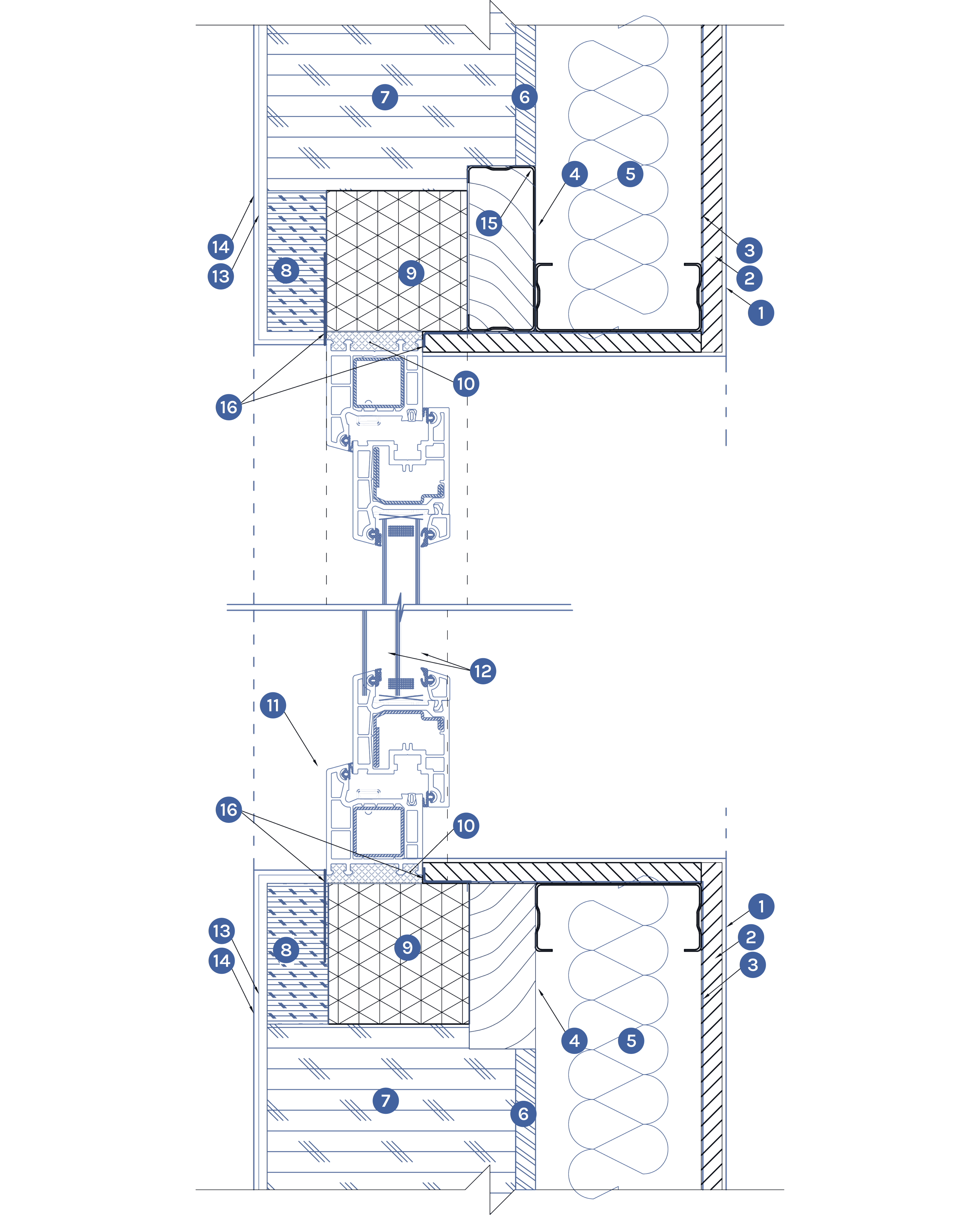

Primary fenestration fixing detail – vertical section

1. Interior finish layer (skim coat + washable paint): ~2.5 mm

2. Gypsum plasterboard: 12.5–25 mm

3. Vapour barrier

4. Lightweight steel stud wall, C100 profiles

5. Thermal insulation within the lightweight steel wall cavity

6. Rigid sheathing board (OSB3, plywood, fibre-cement): min. 12 mm

7. External thermal insulation system (EPS, basalt mineral wool): Tmin = 150 mm

8. Thermal insulation layer (EPS, basalt mineral wool)

9. Pre-frame with polymer adhesive and mechanical fixing

10. Fenestration installation foam

11. Fenestration frame

12. Glazing unit

13. Reinforced render with fiberglass mesh: ~5 mm

14. Decorative render: ~3 mm

15. C-profile lintel stiffening element, lattice beam type

16. Sealing tape (interior and exterior)

Primary fenestration fixing detail – C150 profile wall – horizontal section

1. Interior finish layer (skim coat + washable paint): ~2.5 mm

2. Gypsum plasterboard: 12.5–25 mm

3. Vapour barrier

4. Lightweight steel stud wall, C150 profiles

5. Mineral wool / cellulose insulation

6. Rigid sheathing board (OSB3, plywood, fibre-cement): min. 12 mm

7. External thermal insulation system (EPS, basalt mineral wool): Tmin = 200 mm

8. Thermal insulation layer (EPS, basalt mineral wool)

9. Pre-frame with polymer adhesive and mechanical fixings

10. Fenestration installation foam

11. Fenestration frame

12. Glazing unit

13. Reinforced render with fiberglass mesh: ~5 mm

14. Decorative render: ~3 mm

15. Sealing tape (interior and exterior)

16. Timber frame 40 × 150 mm

Primary fenestration fixing detail – C150 profile wall – vertical section

1. Interior finish layer (skim coat + washable paint): ~2.5 mm

2. Gypsum plasterboard: 12.5–25 mm

3. Vapour barrier

4. Lightweight steel stud wall, C150 profiles

5. Mineral wool / cellulose insulation

6. Rigid sheathing board (OSB3, plywood, fibre-cement): min. 12 mm

7. External thermal insulation system (EPS, basalt mineral wool): Tmin = 150 mm

8. Thermal insulation layer (EPS, basalt mineral wool)

9. Pre-frame with polymer adhesive and mechanical fixings

10. Fenestration installation foam

11. Fenestration frame

12. Glazing unit

13.Reinforced render with fiberglass mesh: ~5 mm

14. Decorative render: ~3 mm

15. C-profile lintel stiffening element, lattice beam type

16. Sealing tape (interior and exterior)

17. Timber frame 40 × 150 mm

WALL INTERSECTION DETAILS

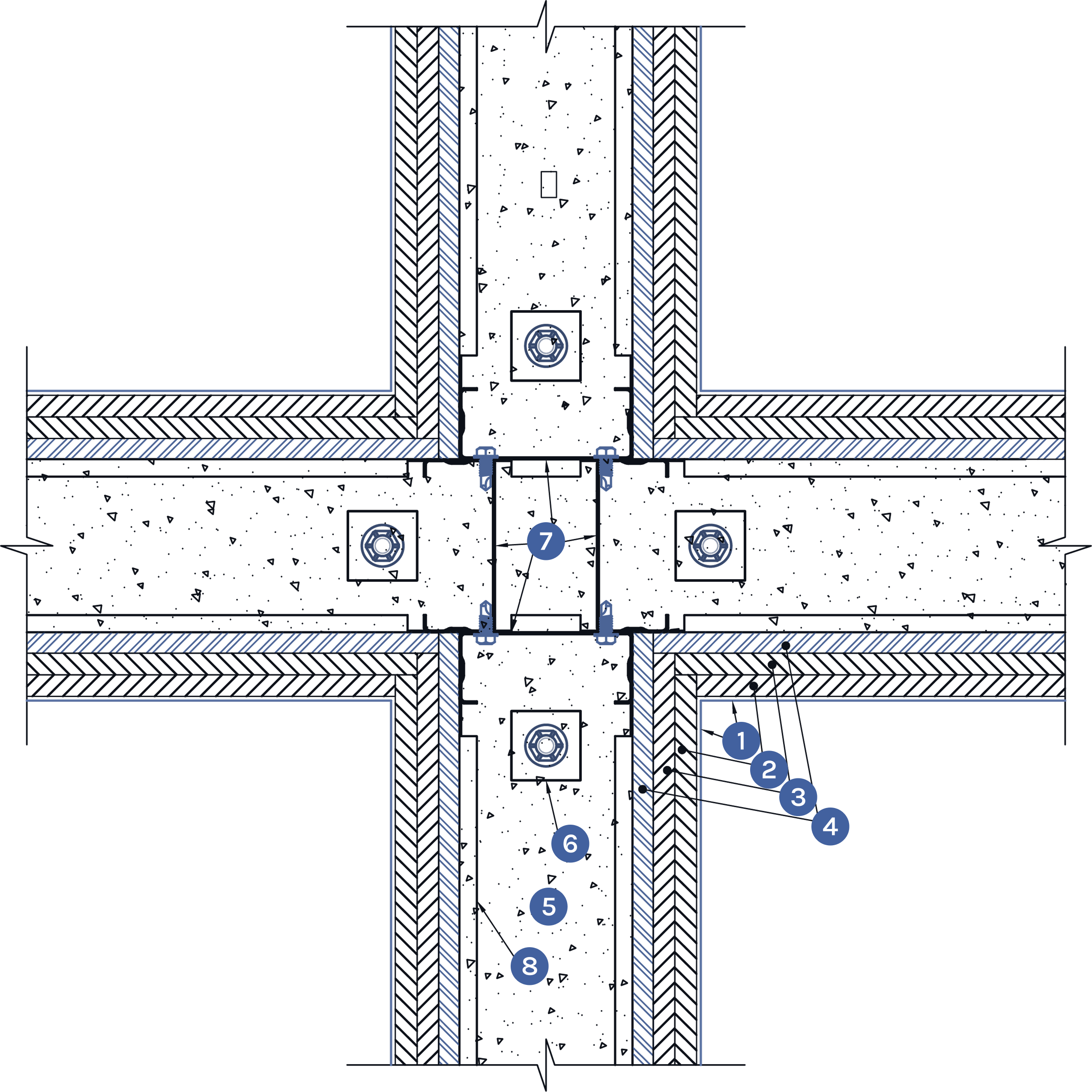

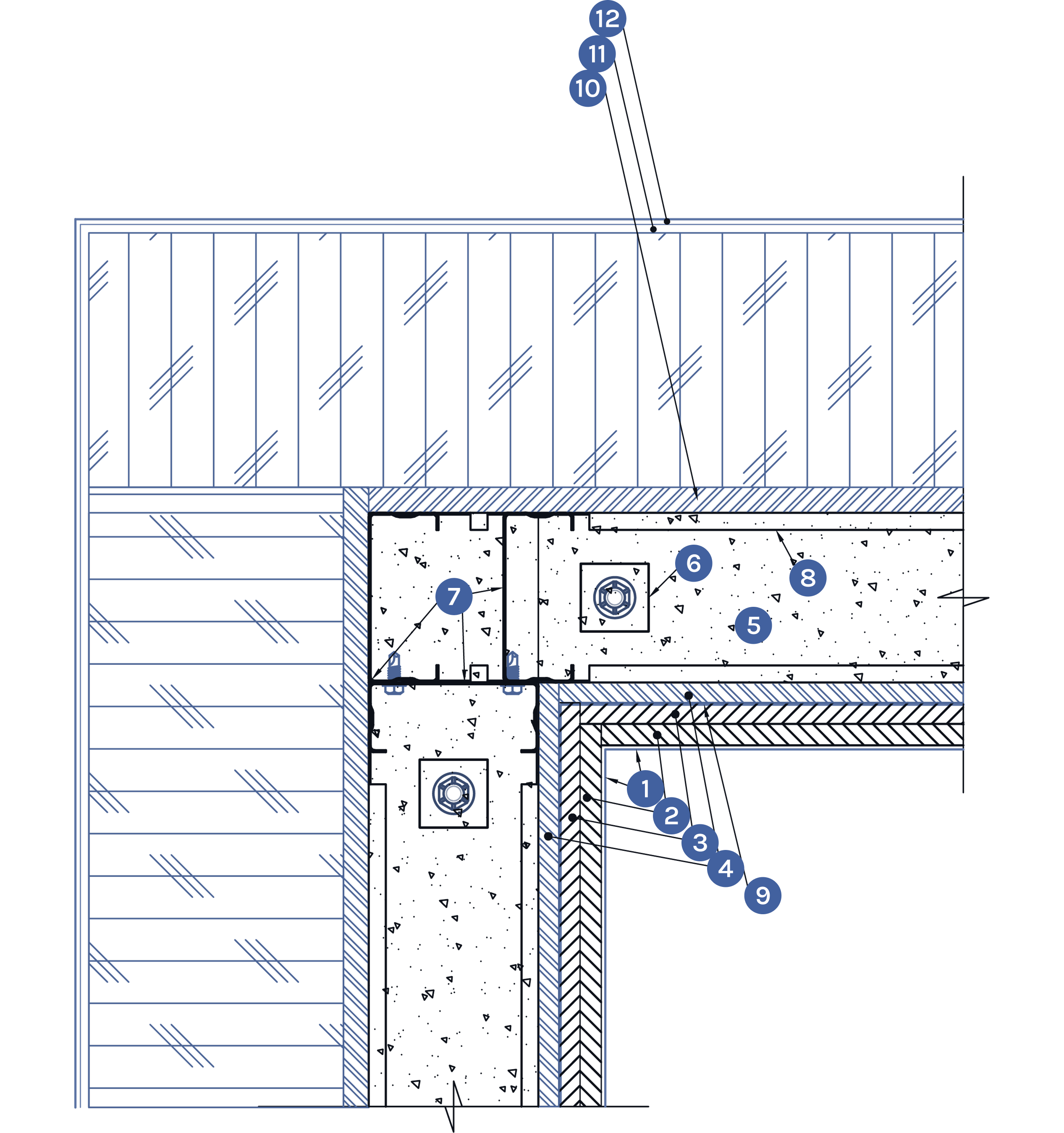

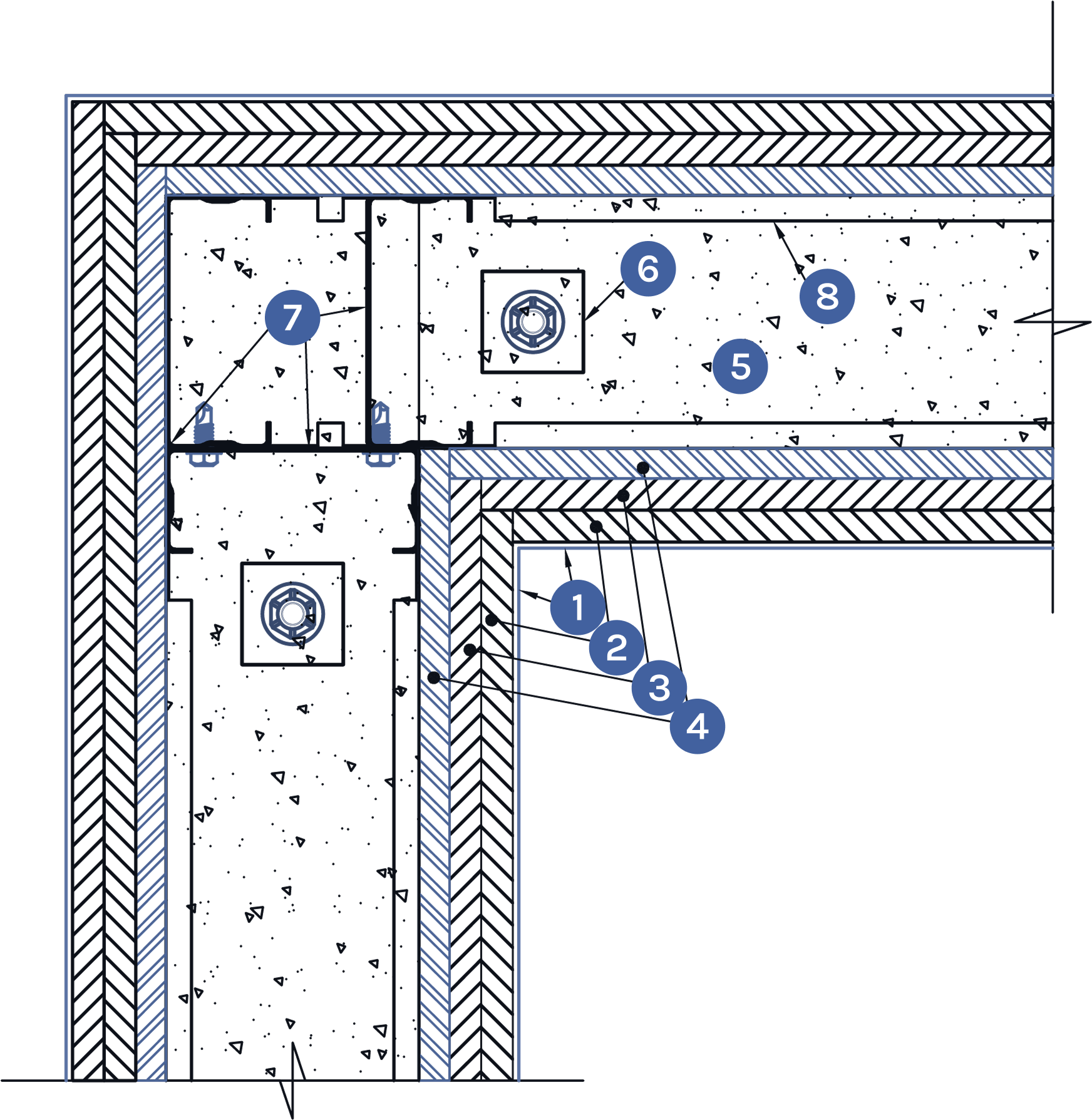

Internal wall intersection – cross junction

1. Interior finish: skim coat + washable paint / adhesive + ceramic tiles

2. Gypsum plasterboard

3. Gypsum plasterboard

4. OSB board

5. Acoustic insulation

6. Mechanical anchor at the bottom track of the wall

7. C-profiles

8. C-profile, wall bottom track

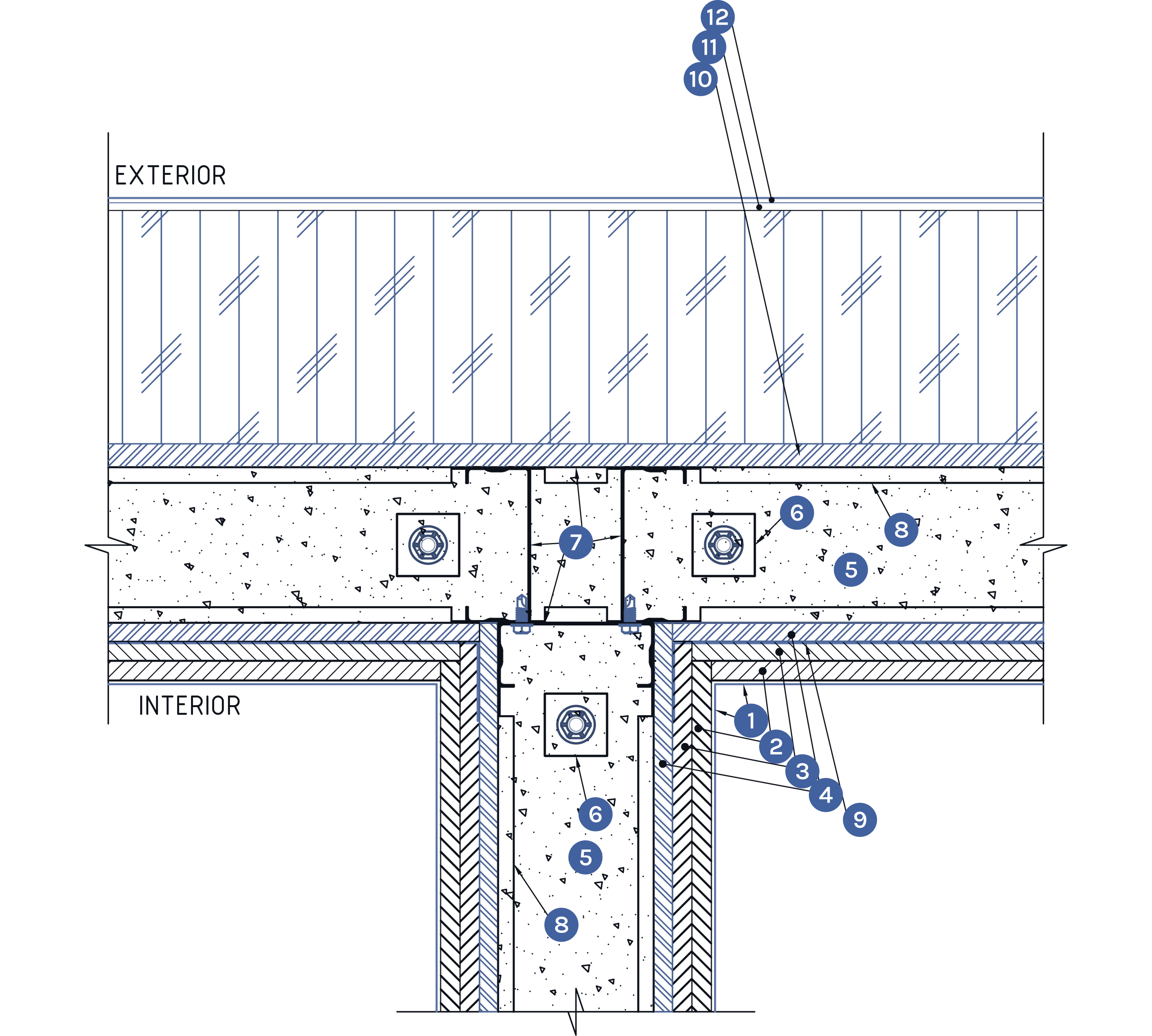

Exterior wall to interior wall intersection

1. Interior finish: skim coat + washable paint / adhesive + ceramic tiles

2. Gypsum plasterboard

3. Gypsum plasterboard

4. OSB board

5. Thermal / acoustic insulation within the lightweight steel wall cavity

6. Mechanical anchor at the bottom track of the wall

7. C-profiles

8. C-profile, wall bottom track

9. Vapour barrier

10. OSB3 board

11. Reinforced render with fiberglass mesh

12. Decorative render

Exterior wall intersection – corner

1. Interior finish: skim coat + washable paint / adhesive + ceramic tiles

2. Gypsum plasterboard

3. Gypsum plasterboard

4. OSB board

5. Thermal / acoustic insulation within the lightweight steel wall cavity

6. Mechanical anchor at the wall bottom track

7. C-profiles

8. C-profile, wall bottom track

9. Vapour barrier

10. OSB3 board

11. Reinforced render with fiberglass mesh

12. Decorative render

Internal wall intersection – corner

1. Interior finish: skim coat + washable paint / adhesive + ceramic tiles

2. Gypsum plasterboard

3. Gypsum plasterboard

4. OSB board

5. Acoustic insulation

6. Mechanical anchor at the wall bottom track

7. C-profiles

8. C-profile, wall bottom track

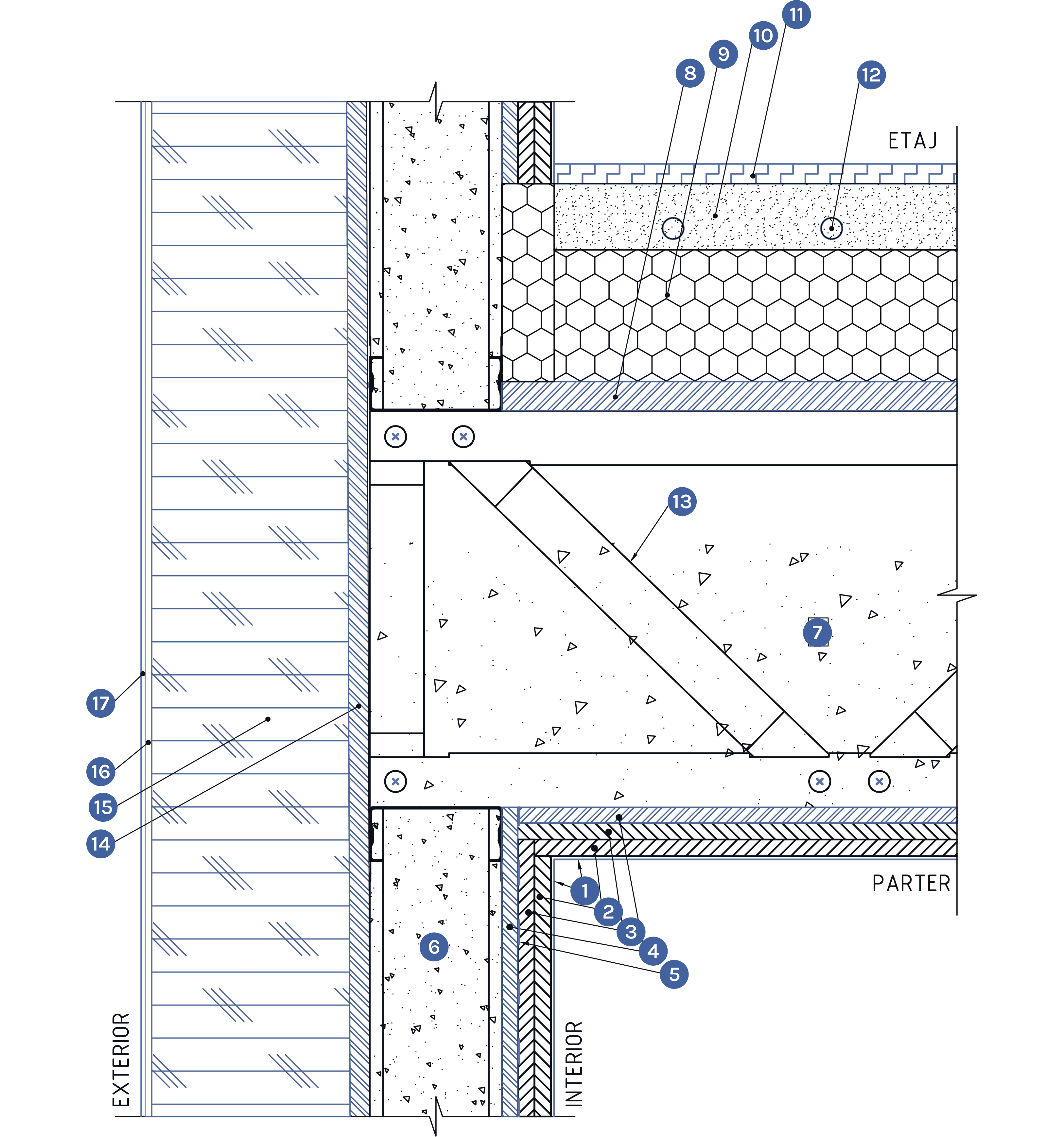

I WALL – FLOOR SLAB – E WALL DETAIL

Detail ground floor wall - floor slab - upper floor wall intersection

1. Interior finish: skim coat + washable paint / adhesive + ceramic tiles

2. Gypsum plasterboard

3. Gypsum plasterboard

4. OSB board

5. Vapour barrier

6. Thermal / acoustic insulation within the lightweight steel wall cavity

7. Thermal / acoustic insulation within the lattice beam floor structure

8. OSB3 board

9. Extruded polystyrene insulation (XPS)

10. Semi-dry screed

11. Floor finish

12. Underfloor heating circuit

13. Lattice beam made of C-profiles

14. OSB3 board

15. External thermal insulation system

16. Reinforced render with fiberglass mesh

17. Decorative render

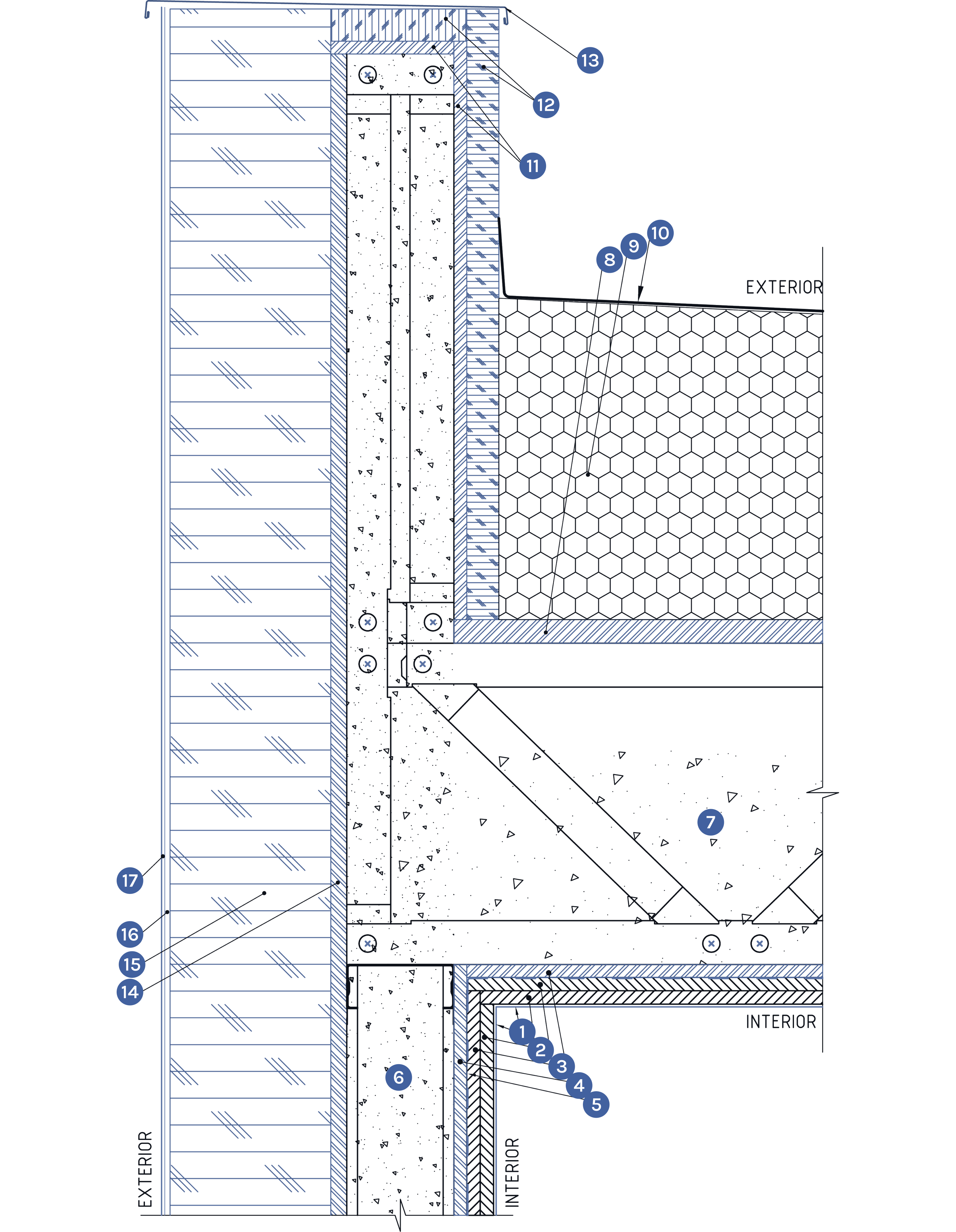

ROOF DETAIL | FLAT ROOF WITH PARAPET

Roof detail - terrace with parapet

1. Interior finish: skim coat + washable paint

2. Gypsum plasterboard

3. Gypsum plasterboard

4. OSB board

5. Vapour barrier

6. Thermal / acoustic insulation within the lightweight steel wall cavity

7. Thermal / acoustic insulation within the lattice beam floor structure

8. OSB3 board

9. Tapered polystyrene insulation

10. Waterproofing membrane

11. OSB board

12. Thermal insulation returned over the parapet

13. Metal parapet coping

14. OSB3 board

15. External thermal insulation system

16. Reinforced render with fiberglass mesh

17Decorative render

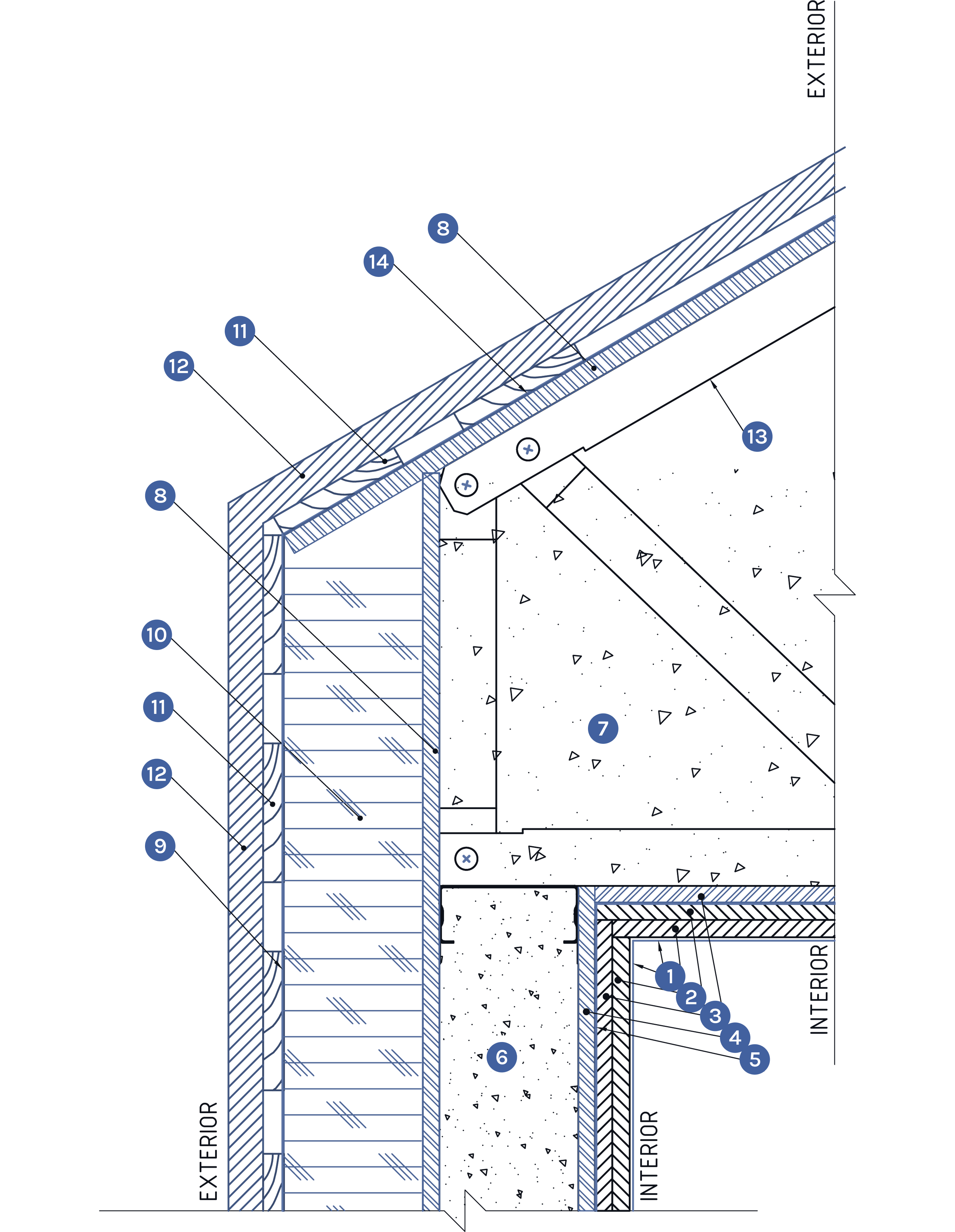

RETROPANEL ENCLOSURE DETAIL

Retropanel enclosure detail

1. Interior finish: skim coat + washable paint / adhesive + ceramic tiles

2. Gypsum plasterboard

3. Gypsum plasterboard

4. OSB board

5. Vapour barrier

6. Thermal / acoustic insulation within the lightweight steel wall cavity

7. Thermal / acoustic insulation within the lattice beam floor structure

8. OSB3 board

9. Breather membrane

10. Vertical supports + thermal insulation system

11. Retropanel support layer (boarding)

12. Retropanel-type boards

13. C-profile truss

14. Anti-condensation membrane

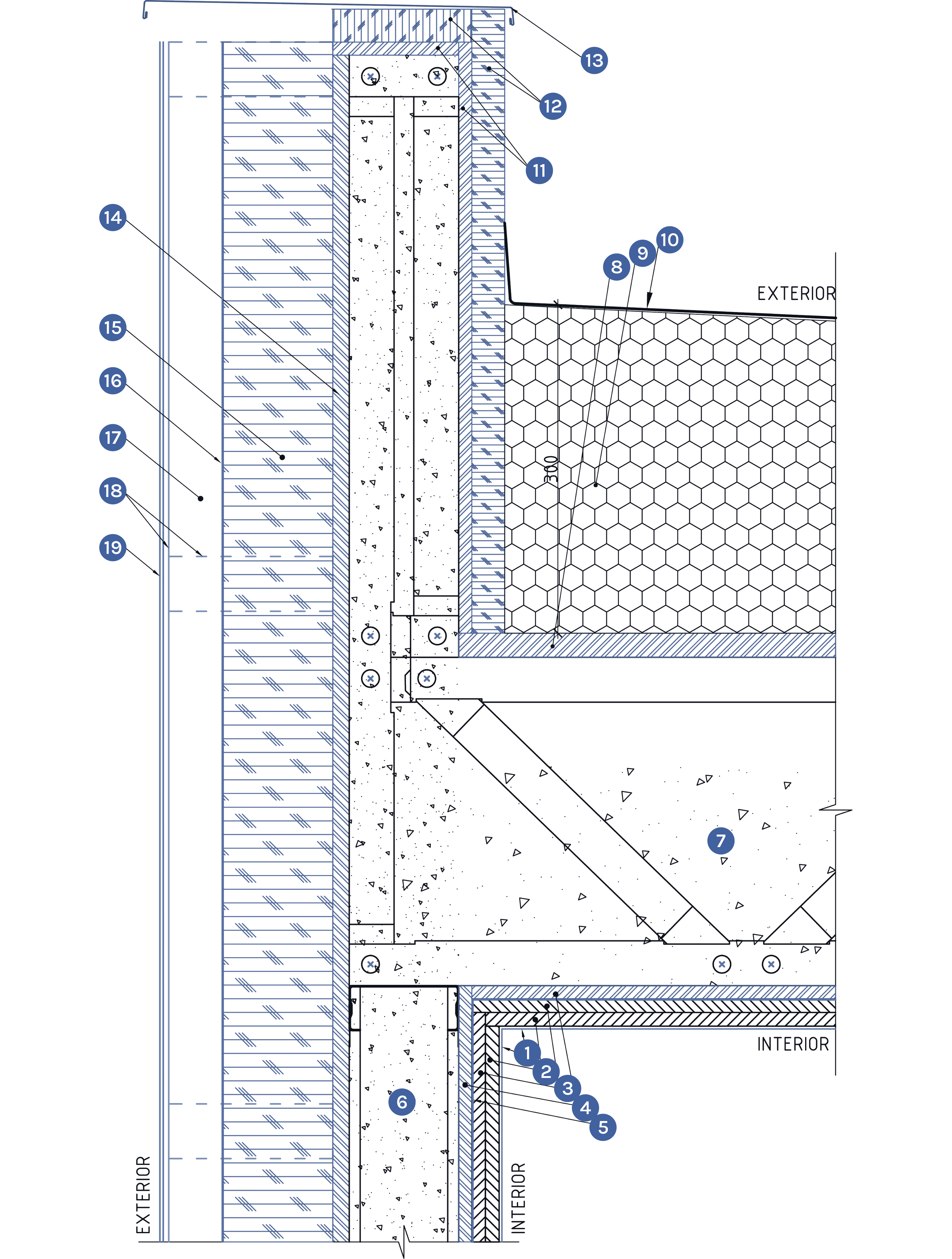

VENTILATED FACADE DETAIL

Ventilated facade detail

1. Interior finish: skim coat + washable paint

2. Gypsum plasterboard

3. Gypsum plasterboard

4. OSB board

5. Vapour barrier

6. Thermal / acoustic insulation within the lightweight steel wall cavity

7. Thermal / acoustic insulation within the lattice beam floor structure

8. OSB3 board

9. Tapered polystyrene insulation

10. Waterproofing membrane

11. OSB board

12. Thermal insulation turned over the parapet

13. Metal parapet coping

14. OSB3 board

15. Thermal insulation

16. Ventilated cavity

17. Ventilated facade framework

18. External cladding

19. Breather membrane

CONTACT

Request a personalized offer